This kit includes all the Mil-Spec quality components you have come to expect from BCM, along with some fantastic upgrades to include; BCM PNT Trigger Assembly, BCM Pistol Grip, Mod 3, BCM Enhanced Trigger Guard.

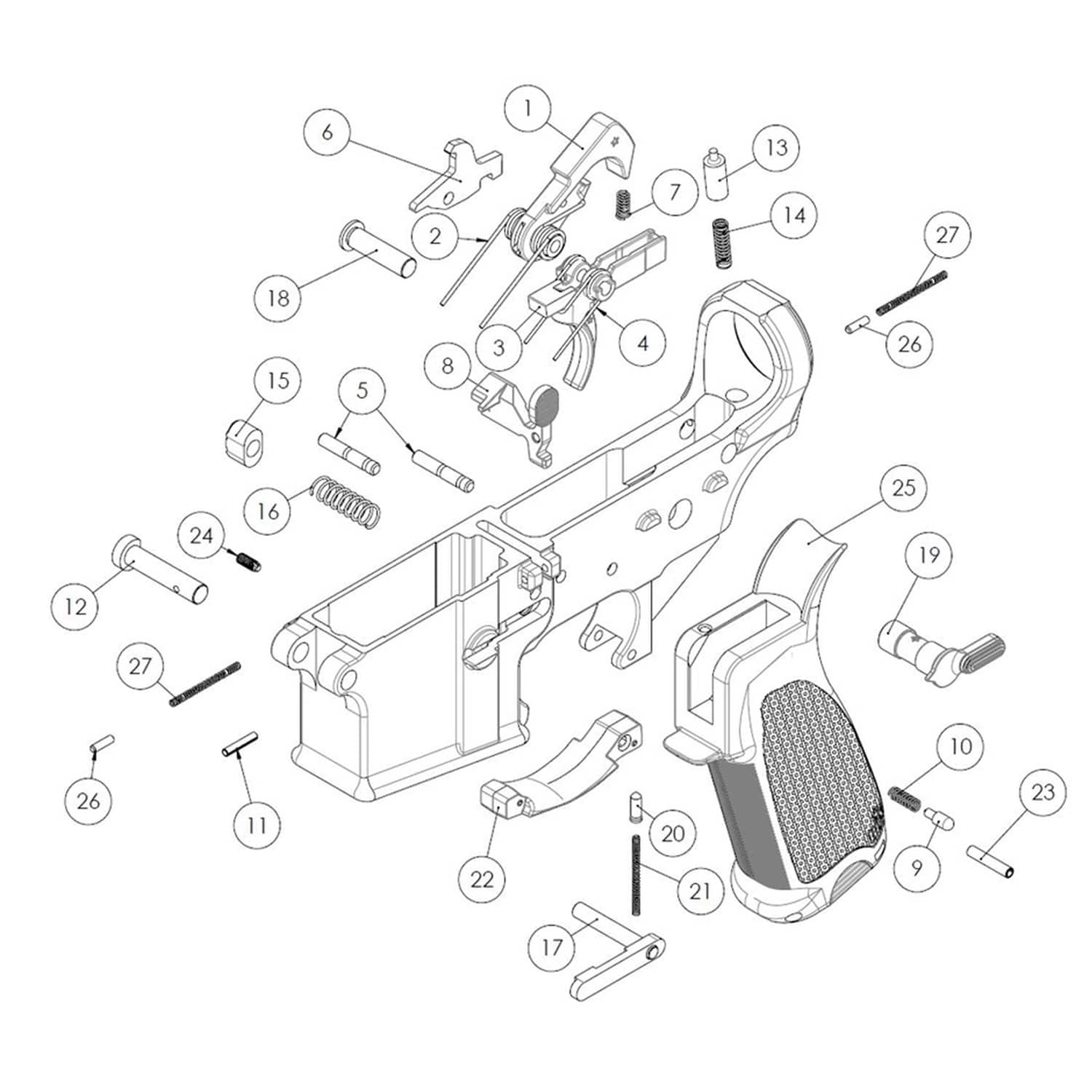

This BCM Enhanced Lower Parts Kit includes:

1. BCM PNT Hammer

2. Hammer Spring

3. BCM PNT Trigger

4. Trigger Spring

5. Hammer/Trigger Pins

6. Disconnector

7. Disconnector Spring

8. Bolt Catch

9. Bolt Catch Plunger

10. Bolt Catch Spring

11. Bolt Stop Pin

12. Rear Pivot Pin

13. Buffer Retainer

14. Buffer Retainer Spring

15. Magazine Catch Button

16. Magazine Catch Spring

17. Magazine Catch

18. Rear Take Down Pin

19. Selector (Safety)

20. Selector Detent

21. Selector Detent Spring

22. BCM Enhanced Trigger Guard

23. BCM Trigger Guard Pin

24. BCM Trigger Guard Screw

25. BCM Pistol Grip Mod 3, Grip Screw, Locking Washer

26. Take Down/ Pivot Pin Detent

27. Take Down/ Pivot Pin Detent Spring

FN America 10.5" Barrel BB M16 Carbine Length Gas System - 5.56

FN America 10.5" Barrel BB M16 Carbine Length Gas System - 5.56

Aero Precision Enhanced Carbine Buffer Kit for AR-10

$104.99 – $105.57

Aero Precision Enhanced Carbine Buffer Kit for AR-10

$104.99 – $105.57

Daniel Defense DDM4 V7 LW Upper Receiver - 16"

Daniel Defense DDM4 V7 LW Upper Receiver - 16"

Sons of Liberty Gun Works A5H2 Buffer Kit - Green Spring

$179.60

Sons of Liberty Gun Works A5H2 Buffer Kit - Green Spring

$179.60